Common Causes of Power Cable Failure

1. Mechanical Damage

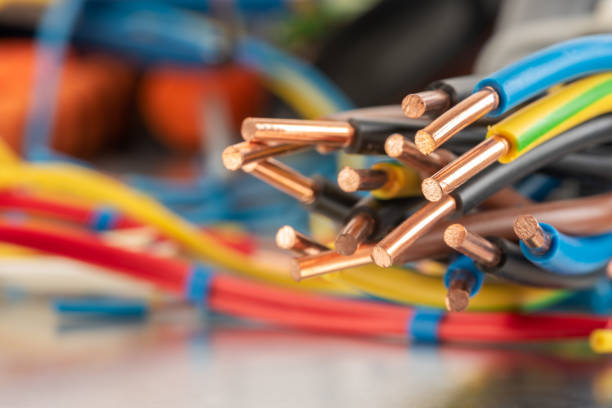

Power cables are like hoses that carry electricity to different parts of your house, from the bulk wires to the extension cords, not leaving out the outdoor extension cord. They may occasionally become squashed, overly bent, or scraped, much like a garden hose that may sustain damage from being stepped on or snagged on something sharp.

Power cables must be handled cautiously when being installed or serviced. They can get bad if they are bent too much or if anything heavy is placed on them; over time, this weakens them. This may facilitate the release of electrical current or result in the cables cutting out completely.

2. Environmental Factors

Environmental conditions are among the most prominent reasons for power cable failure. As power moves from one location to another, your power cable keeps it safe. However, excessive sun or rain exposure can cause it to wear out. Here are a few ways the environment might harm power cables:

- Extreme Temperatures: Consider how objects can expand or contract in extremely hot or cold temperatures. Also, power cables might stretch and compress when it’s too hot or cold outside. They may become weaker and more brittle because of this continual alteration.

- Moisture: Power cables are not friends with water. Water entering a cable might lead to issues such as a short circuit or power flowing where it shouldn’t.

- Chemicals: Just like some substances can ruin your favorite shirt, certain chemicals in the soil or air can eat away at the outer layer of power cables, making them weaker and more prone to breaking.

- UV Radiation: Do you know how the sun’s rays can fade colors? Well, they can also damage the outer covering of power cables, making them brittle and more likely to crack.

When your power cables are exposed to these conditions, they’re prone to danger, posing risks to even the most robust electrical outlets in the building, like NEMA 5-15r and 5-15p, GFCI extension cord, and the electronics plugged into them.

3. Overloading

There is a limit to how much electricity power cables can safely transport between locations. So, if you feed them too much electricity, they may become overwhelmed.

Overloading is when an excessive amount of electricity passes through a cable. This may occur for several causes. Perhaps a rapid spike in power consumption results from multiple devices being used concurrently, such as when various people in your home use hair dryers simultaneously.

Or maybe a fault in the electrical system causes more electricity to flow through the cables than they can handle.

Overloading cables might cause them to heat up. The heat may harm the protective covering outside the cables and the insulation surrounding them. Fires or short circuits may result from damage to the insulation.

4. Manufacturing Defects

Manufacturing defects are mistakes or problems that happen when making power cables, making them one of the common causes of power cable failures. It’s similar to baking cookies; some turn up burned or without certain ingredients. These flaws can include excessively thin insulation (the protective covering) or undesirable substances (impurities) in the materials utilized.

These problems weaken the cable and increase the likelihood of failure. In the same way, you might proofread your project before turning it in, companies must thoroughly inspect the wires during and after manufacture to prevent this. This makes it less probable that later issues will arise from high-quality cables.

5. Biological Factors

Biological factors, like animals and plants, can wreak havoc on power cables. Just like rats can chew on NEMA plugs or rocker switch wiring, cables or plants growing around them are not left out! These critters cause damage by gnawing through the insulation or making nests near cables.

This exposes the wires and can lead to short circuits or even fires.

Insects can also be problematic, as they burrow into cables and cause similar issues. To prevent this, we must use materials that animals and plants won’t find tasty or comfy.

6. Poor Installation Practices

Poor installation practices can be a big reason power cables fail. Imagine if you put a puzzle together, but some pieces don’t fit right or are in the wrong place. Similarly, cables can get stressed out or bent weirdly when installed incorrectly.

This stress can weaken them over time, making them more likely to break or stop working correctly. It’s like building a weak bridge that might collapse because it wasn’t put together. This doesn’t happen with cables alone. Even in something as simple as abulk extension cord, pinching, crushing, or cutting the cord during installation can weaken the insulation and expose wires, creating safety hazards and increasing the risk of electrical shock or fire.

Addressing Root Causes of Power Cable Failure

1. Preventive Maintenance

The first on our list of ways to address these root causes is preventive maintenance. Physical protection of power cables involves installing barriers and shields to keep them safe from harm. It’s a delicate lifeline that needs to be shielded from anything that could hurt it. Power cables need their armor, like how you wear protective gear when riding a bike or playing sports.

This armor can come in different forms, like sturdy plastic conduits or metal guards, depending on where the cables are installed and what threats they face. These shields act as a barrier, keeping cables safe from rocks, sharp objects, or curious animals that might chew on them.

With these protective layers, you ensure the cable stays strong and healthy, preventing damage that could lead to failures and power outages. So, just like how you protect the little electrical components like your c13 plug in the house, the power cables that supply the significant electricity also need protection to stay safe and keep the electricity flowing smoothly.

2. Quality Assurance

Quality assurance ensures that our power cables meet high standards and are reliable. It’s nothing much except ensuring the cables are solid and safe before use.

First, ensure the wires are constructed appropriately and with suitable materials. In the same manner, before making a purchase, you’ll ask a switch power cord vendor all the questions you have. Once the materials have been confirmed, you can test the cables to ensure they function well and won’t break easily.

You can also collaborate closely with reputable manufacturers to guarantee that the cables are of high quality. This way, you can feel even more secure knowing it comes from a reliable and confirmed source. Conducting these inspections may increase your confidence that the cables will function well and cause no issues.

Good quality cables are essential to keep our electricity running safely and smoothly.

3. Environmental Protection

Environmental protection is one strategy for addressing the underlying causes of power cable failure. Electrical cables must be kept safe from dangerous substances in their immediate vicinity to safeguard the environment. Let’s say you own a pet fish. You must ensure the water in its tank is clean and free of potentially harmful things.

Similarly, electrical cables must be shielded from potentially damaging elements, including water, chemicals, and high temperatures.

You can achieve this by covering the cords with unique materials. You can bury cables underground or house them in tubes to protect them from rain, snow, and other weather. The same treatment you give an electric cord indoors should be given to these cables, too!

Just like taking care of your fish’s surroundings keeps it healthy and happy, protecting electrical cables from these environmental threats guarantees they survive longer and operate better. This will ensure energy flows appropriately to your homes and businesses and prevent issues like short circuits and power outages.

4. Load Management

Monitoring your electricity usage and ensuring you don’t consume too much is known as load management. An overloaded power cord can act strangely and give rise to several problems. Similar to how multiple electrical devices put into a NEMA plug can cause it and related wiring to become overloaded, this is also possible.

Similar to this, power cables have a maximum safe electrical carrying capacity. They may become overheated and cease to function if you consume more electricity than they can manage, which could lead to a blackout or fire.

You must be careful not to overload the cords to avoid this. You must balance the amount to prevent any single wire from carrying too much power. To achieve this, the electricity should be distributed evenly among the many cables, and each one should only be used for the purpose for which it was intended.

It may occasionally be necessary to replace your hardware or add backup systems to assist in spreading the workload. By carefully controlling your electricity, you can protect the cables and prevent issues like blackouts and fires.

5. Self-healing Materials

Self-healing materials represent an innovative approach to mitigating damage in power cable insulation. These materials are engineered with embedded microcapsules or polymers. These polymers can autonomously repair small cracks or breaches because of mechanical stress or environmental factors.

When damage occurs, the self-healing mechanism is triggered, releasing healing agents that flow into the affected area and fill in gaps or restore integrity to the insulation. This self-repair process helps prevent further degradation, extending the cable’s lifespan and reducing the need for external protection measures.

Developing self-healing materials for power cables holds significant potential for enhancing reliability and reducing maintenance costs. By enabling cables to repair themselves in situ, these materials can minimize downtime, mitigate risks associated with insulation failure, and improve overall system resilience. Also, self-healing technology can extend cable lifespan in harsh operating environments where physical protection may be impractical or insufficient.

As research advances, self-healing materials could become a valuable asset in ensuring the longevity and performance of power cable infrastructure. But till then, other strategies should suffice and yield better results!

6. Training and Education

Imagine you’re learning to care for something important, like a pet. Just like you need to learn how to feed, clean, and keep your pet healthy, people who work with power cables also need to learn how to care for them properly.

In training and education, people who work with power cables learn how to handle them safely, install them correctly, and ensure they stay in good shape. They learn things like spotting problems before they become significant issues, protecting cables from getting hurt by water or animals, and ensuring they’re not carrying too much electricity.

With these skills, people can ensure that power cables stay healthy and strong, which helps prevent them from breaking or causing problems. Just like taking good care of a pet keeps it happy and safe, taking good care of power cables keeps our electricity running smoothly and safely.

Conclusion

In summary, physical damage, inclement weather, overloading, and installation errors are the leading causes of power cable failures. We can prevent them by using high-quality cables, shielding them from the elements, testing them frequently, and ensuring we don’t use excessive electricity.

It’s also important to be careful when installing cables and adequately training people. By taking these steps, we can ensure that our power lines function correctly and maintain the safe flow of electricity to the areas that require it.